Thin film deposition is the process of applying a very thin film of coatings onto a substrate to form layers. Let’s take a look at the history of thin-film deposition, its applications in materials science and how this innovative technology has changed our world.

A Brief History of Thin-Film Deposition and Its Applications in Materials Science

Many objects that we take for granted today – including solar panels, optical devices, anti-reflection coatings, biosensors, and more – depend on atomic-scale thin-film deposition. When did thin-film deposition begin, and why is it so important?

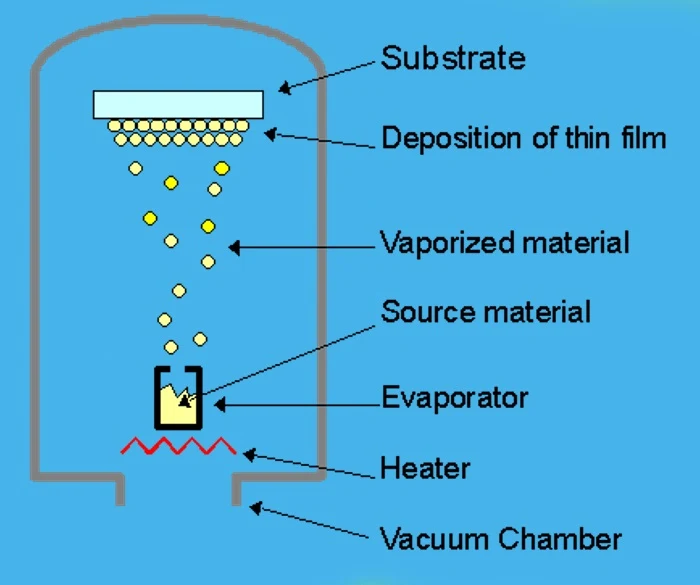

In basic terms, thin-film deposition means applying a thin layer of film, from single-layer atoms up to several micrometres, to a surface. Deposition technologies fall under two broad categories: chemical deposition and physical deposition.

Keep reading to learn more about the history of thin-film deposition and how this innovative technology changed our world.

An Overview of Thin Film Across Its History

Today, a thin-film deposition company can use advanced deposition techniques to create flexible, modular deposition systems with diverse applications. These technological achievements are possible thanks to the world-changing work and research of thin-film pioneers.

Thin Films in Antiquity

The first documented use of thin films dates from over 5000 years ago. Ancient Egyptians would deposit gold films on jewellery, statues, and religious artefacts.

Using a somewhat different chemical deposition technique, the Moche people of Peru also deposited layers of thin metal coating on various artefacts, starting from circa 100 B.C.

Modern History of Thin Film Deposition

In 1652, the German scientist Otto von Guericke developed the first vacuum system. Two centuries later, William Robert Grove, a Welsh physicist, conducted the first physical sputter deposition experiments using von Guericke’s high vacuum method and a DC voltaic pile to deposit iron oxide on a silver substrate.

By the late 19th century, scientists were already using sputter-deposited metal films as optical coatings on lenses. In 1921, Albert Hull presented the magnetron, a vacuum-tube device that brought a higher level of speed and accuracy into thin film deposition.

Thin-Film Deposition Today

In 1970, Peter J. Clarke introduced the sputter gun, a device that enabled atomic-level thin-film coating by using ion and electron collisions. This technology, known as plasma sputter, forms the basis of modern physical vapour deposition (PVD).

Subsequent discoveries, such as atomic-resolution surface imaging and in-situ techniques, refined thin-film deposition technologies and broadened its scope of applications.

How Thin Films Are Used Today

Today, entire industries rely on the ability to deposit pure, atomic-scale thin films onto a variety of substrates. Thin films play a vital part in:

- Implants and biosensors

- Thin-film batteries

- Optoelectronic applications like precision optics and optical filters

- LED displays and other consumer electronics

- Photovoltaic cells

Thin-film technology continues to evolve and benefit diverse industries. For example, in the coronavirus era, innovative thin-film chips enabled the manufacture of no-contact thermometers. Likewise, in recent years, thin-film techniques have made the transition to renewable energy more practical and affordable through its usage in photovoltaic solar panel production.

Final Thoughts

The history of thin-film deposition and its various applications has had a tremendous impact on humankind. Atomic-precision thin films allowed the development of many devices that form an inseparable part of our day-to-day lives.

Today, research continues to perfect deposition technologies and improve thin-film performance. This valuable process will continue to be central to industrial, biomedical, and environmental endeavors for many decades to come.